Understanding of UV

Understanding of Anti-UV Coating

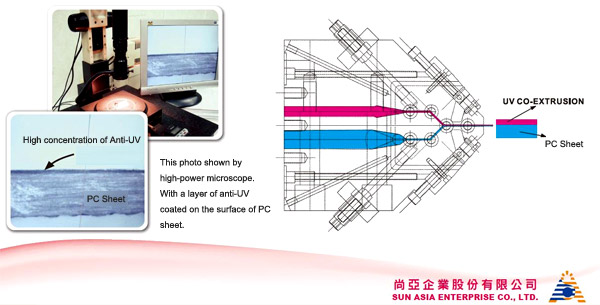

With a layer of anti-UV coated on the surface during the process of co-extrusion could prolong the lifespan of the sheet. Purpose of the anti-UV coating is to prevent ultraviolet from shining through which could cause the sheet from turning yellowish and ends with crack. Polycarbonate sheet maintains an excellent transparency surface over a period of time compare to others.

The Way of Anti-UV Coating:

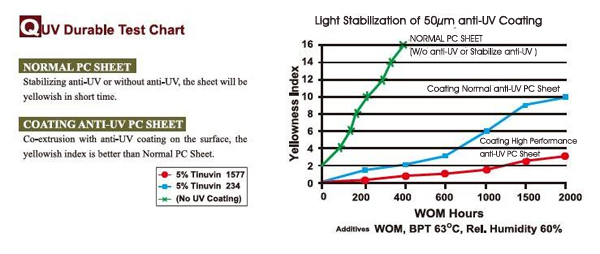

QUV Durable Test:

| Production Mode | Yellowish fig. | Years of Yellowish |

|---|---|---|

| UV W/o anti-UV | Above Δ YI 40 | Yellowish in short time |

| UV Stabilize anti-UV | Δ YI 10 ~ 15 | 2 ~ 3 years |

| UV Coating Normal anti-UV | Δ YI 3~7 | 3 ~ 5 years |

| UV Coating High Performance anti-UV | Below Δ YI 6 | 10 years & above |

Polycarbonate sheet with Anti-UV coating not only reduces ultraviolet from transmitting but also protect Polycarbonate sheet against any harmful damage and prolong properties of Polycarbonate Sheet. Surface of the sheet form a protective force against factory pollution, exhaust emission from vehicles, dust and acid rain stain. It enables the sheet to maintain as new as it is.

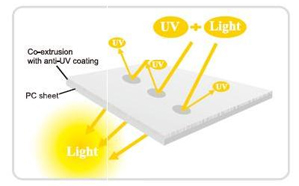

Co-extrusion with Anti-UV coating on the surface shall effectively blocking harmful ultraviolet rays, protect against ultraviolet from transmitting which cause sheet to crack, turn yellow and effectively maintain physical properties of Polycarbonate.

UV Degradation

FAQ: What waviness of UV causes biggest damage to Polycarbonte?

A:

UV-A: 320nm ~ 380nm

-Influence of UV-A on polymer: It might cause some certain polymers to degrade.

-Influence of UV-A on human: In general, there is no harm to human body, but human often expose under the UV-A during the life time. The UV-A permeates deeply and strongly so that skin becomes lack of elasticity easily.

UV-B: 280nm ~ 320nm

-Influence of UV-B on polymer: This is the lowest waviness of sun light, and mainly causes polymers to degrade.

-Influence of UV-B on human: UV-B is strongest during 10 AM to 2 PM. UV-B would make skin rough, sensitive, weak, and even become skin cancer. It's easy to get sunburn because of UV-B.

UV-C: lower than 280nm

-Influence of UV-C on polymer: UV-C would cause some abnormal effects on polymers.

-Influence of UV-C on human: UV-C can destroy microorganism. UV-C is absorbed by ozonosphere while passing the atmosphere. As the results, UV-C wouldn't cause any damage to skin.

Certain waviness which might cause biggest damage:

| Polymer | Certain waviness which might cause biggest damage (nm) |

|---|---|

| Polyvinyl acetate | < 280 |

| Polycarbonate (PC) | 285, 305, 330, 360 |

| PMMA | 290, 325 |

| SAN | 290, 325 |

| PE | 300 |

| PP | 310, 370 |

| PS | 319 |

| PVC | 320 |

| PET / PBT | 325 |

| PA | 280 - 290, 300 - 320 |

The QUV weather ability test of Polycarbonate boards made by SUN ASIA:

| Ways | The Index Of Yellowing | Useful Life Without Yellowing |

|---|---|---|

| No Anti-UV | Higher than 40 | Yellowing at A Short Time |

| Anti-UV Contain | 10 ~ 15 | 1 ~ 2 Years |

| General Anti-UV Coating | 3 ~ 7 | 3 ~ 5 Years |

| Long-Lasting Anti-UV Coating | Lower than 6 | Lower than 10 Years |

Data criterion above is base on 313nm for this test.