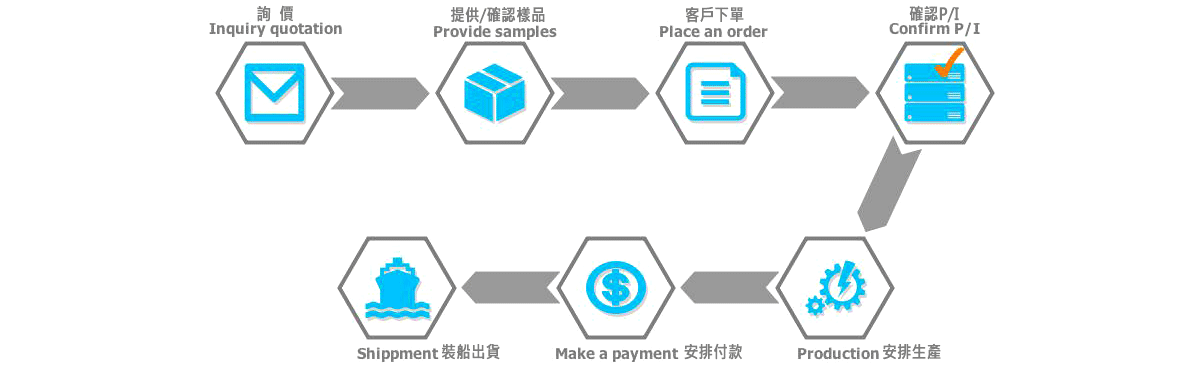

Process Flow

Production Process

Receive complete "order confirmation" from sales department, production management division will turn it into "production order" and establish process control time table, and then execute by production division and quality assurance division. The production schedule is carefully monitored section by section.

Assembly and quality check process follows "producing control inspection regulation" to ensure operations and production quality.

To shorten customer waiting time for delivery, production management division will set up annual advanced batch production plans to effectively control machine and parts stock safety, so that delivery schedules can be reduced to a minimum.

Identification and Traceability of Parts and Machine Information

The parts and semi-finished products produced by the production process follow "shipping, storage, packing and delivering control regulation" guidelines to be aligned in their pre-designated positions clearly marked product name, specification, part number, order number and current status, in order to eliminate the possibility of parts missing or being taken by error.

The production inspection process is followed with a "producing inspection form" that is to be checked item by item and signed by the same engineer who does the check, so that when performing after-sales servicing, the machine's past records can be easily traced.